How does a laser cutter work? Features and Functions

What are the laser cutter of laser cutting?

Before we move on how does a laser cutter work, lets discuss about the benefit of using this new technology. First of all, laser cutting will generate parts with the highest standard of precision. Laser cutters are extremely right and capable of making great details and complex cuts providing you a lot of design freedom. The laser machines cut materials actually the way your design goes, there is no room for error.

Laser cutters are completely automated, which keeps a lot of production time. All there is to do to workers is moving stuffs. That fact leads to low material wastage and lowers the production costs. Hand-free cutting machines are quick and effective, making the producing process simple and quick.

Laser cutting also means a big range of materials, one of which will definitely meet your production needs.

Last but not least, laser cutting machines are also able of laser engraving providing you even more ways to develop your projects and find the best solution for your production. With laser engraving, you can bring different dimensions and depth to your projects.

How does a laser cutter work?

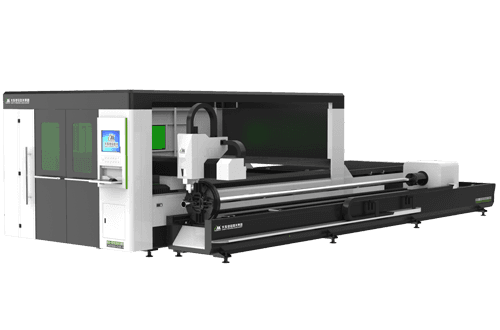

Laser cutting is a digital producing technology, working on 2D vector files. The laser cutter itself is built of a laser resonator which, depending on the cutting technique, contains a either mixture of a glass fibers or crystal body. The cutting process begins when energy is applied to the mixture, which is then sent via different mirror lenses targeting the laser.

Thanks to the series of mirrors, the laser beam is send via nozzle straight at the stuff. When it makes contact with the surface, it vaporizes the stuff in the shape of the vector file. Part of the stuff which is melted with the laser is known as kerf and needs to be considered in your design.

A laser cutter is a strong machine. We know it and that is why we provide you with the top materials to meet your production needs.

We also use our laser cutting machines for wood materials such as plywood with five different color choices and three thickness across both catalogs, and Laser Mdf Cutting Machine in seven colors.

Laser cutting can generate some amazing projects. It can be used in different industries, from mechanical engineering and more technical to decorative. A best example of a functional application of laser cutting is table project for an exhibition in Lyon.

Article source: https://www.hansymlaser.com/news/how-does-a-laser-cutter-work

Media Contact

Company Name: Han’s Yueming Laser Group Co.,Ltd.

Contact Person: Media Relations

Email: Send Email

Phone: +86-769-22705851

Country: China

Website: https://www.hansymlaser.com/